PRODUCT RANGE

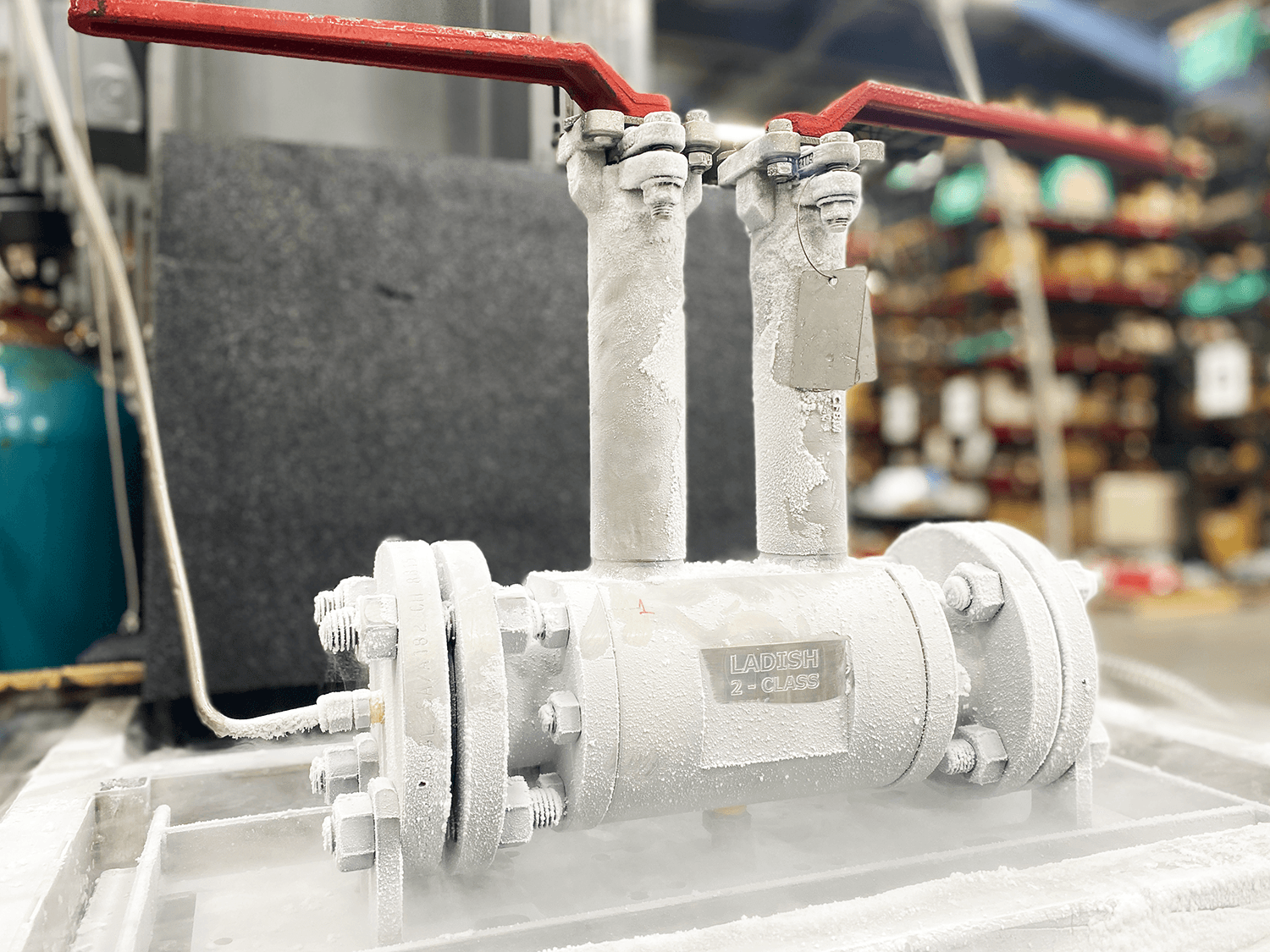

CAST CRYOGENIC

Ladish Valves stainless steel cryogenic valves are produced to the rigid ‘Controlled Quality’ standards that assure dependable operating performance at sub-zero temperatures. The production, transport and storage of liquefied gases such as oxygen, nitrogen, natural gas (down to –425°F) demand a thoughtful solution.

Figure Numbers

8293, 8294, 8295, 8299, 8393, 8394, 8395, 8399, 8693, 8694, 8695, 8699, 8995, 8999, 8595, 8599

Design

API 600, API 603, and ASME B16.34 and MSS-SP134

Size

½” thru 30”

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

Figure Numbers

7290, 7291, 7292, 7296, 7390, 7391, 7392, 7396, 7690, 7691, 7692, 7696, 7992, 7996, 7592, 7596

Design

API 623, ASME B16.34 and MSS-SP134

Size

½” thru 16”

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

Figure Numbers

5290, 5291, 5292, 5296, 5390, 5391, 5392, 5396, 5690, 5691, 5692, 5696, 5992, 5996, 5592, 5596

Design

API 594, ASME B16.34 and MSS-SP134

Size

½” thru 36”

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

Figure Numbers

P7, P8, P9

Design

API 608 and ASME B16.34 and MSS-SP134

Size

½” thru 14”

Pressure Rating

150 thru 600

End Connections

Flanged / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

PRODUCT RANGE

FORGED CRYOGENIC

Ladish Valves ability to manufacture specifically designed cryogenic valves and to convert standard valves to cryogenic service, all in-house, allows for a completely controlled quality process. In addition, custom modification requests and any associated non-destructive testing can be expedited. Cryogenic testing per BS 6364 can also be facilitated from our headquarters in Houston.

Figure Numbers

8793, 8794, 8799, 8193, 8194, 8199, 8893, 8894, 8899, 8593, 8594, 8599, 8295, 8395, 8695, 8995, 8595

Design

API 602, ASME B16.34 and MSS-SP134

Size

½” thru 4″

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

Figure Numbers

7790, 7791, 7796, 7190, 7191, 7196, 7890, 7891, 7896, 7590, 7591, 7596, 7295, 7395, 7695, 7995, 7595

Design

API 602, ASME B16.34 and MSS-SP134

Size

½” thru 4″

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)

Figure Numbers

5890, 5891, 5896, 5292, 5392, 5682, 5193, 5590, 5591, 5596, 5282, 5382, 5682, 5182

Design

API 602, ASME B16.34 and MSS-SP134

Size

½” thru 4″

Pressure Rating

150 thru 2500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / Hastelloys / Monel

Testing

Non Cold Box API 598 / Cold Box Testing MSS-SP134 / BS 6364 (Optional)