PRODUCT RANGE

FORGED GATE / GLOBE / CHECK

Ladish Valves stocks these valves in a variety of materials from carbon steel to nickel alloy and pressure classes ranging from 150 to 4500. In addition, both reduced and full ports and welded or bolted bonnet joints are available. Our 80,000 sq ft facility allows for inventory storage, product testing and material conformance control. With in-house NDE capabilities and fully integrated machine shop, quick deliveries and unconventional customer requirements are achieved in a timely, quality controlled manner.

Design

API 602 AND ASME B16.34

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal, Bonnetless, Bellowseal

Construction

T-Pattern / Y-Pattern

Design

API 602 AND ASME B16.34

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal, Bonnetless, Bellowseal

Construction

T-Pattern / Y-Pattern

Design

API 602 AND ASME B16.34 / Bolted Cover

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal

Construction

T-Pattern / Y-Pattern

PRODUCT RANGE

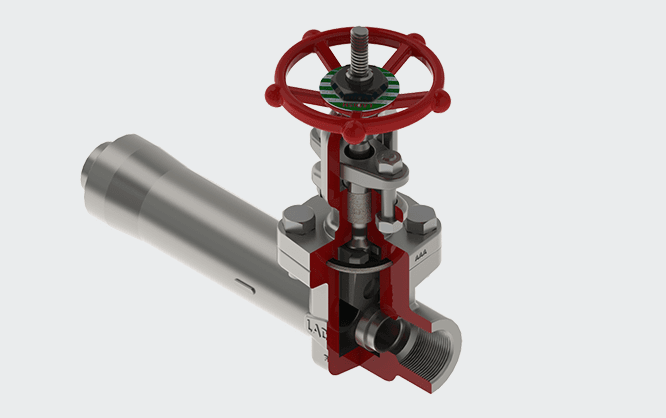

FORGED STEEL HIGH PRESSURE GATE / GLOBE / CHECK

Typical design for Ladish high pressure valve would be bonnetless, pressure seal or welded bonnet configuration, either in a T-pattern or Y-pattern design. Typical applications for Ladish forged steel high pressure valves span the oil & gas, chemical, refining and power markets. In addition, high pressure valves are frequently demanded for difficult service.

Figure Numbers

8523/8524, 8023/8024, 8D23/8D24, 8163/8164, 8463/8464, 8A63/8A64

Design

API 602 AND ASME B16.34

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal, Bonnetless, Bellowseal

Construction

T-Pattern / Y-Pattern

Figure Numbers

7510/7511, 7010/7011, 7D10/7D11, 6510/6511, 6010, 6D10/6D11, 7520/7521, 7020/7021, 7D20/7D21, 7160/7161, 7460/7461, 7A60/7A61

Design

API 602 AND ASME B16.34

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal, Bonnetless, Bellowseal

Construction

T-Pattern / Y-Pattern

Figure Numbers

5520/5521, 5020/5021, 5D20/5D21, 5170/5171, 5470/5471, 5A70/5A71

Design

API 602 AND ASME B16.34

Size

½” thru 4”

Pressure Rating

150 thru 4500

End Connections

Flanged / Threaded / Socket Weld / Buttweld

Materials

300 Series Stainless / A105 and Low Temp Carbon / Alloy 20 / Duplex / Nickel Alloys

Testing

API 598

Body-Bonnet Connection

Bolted, Welded, Pressure Seal

Construction

T-Pattern / Y-Pattern