Capabilities and Services

Overview

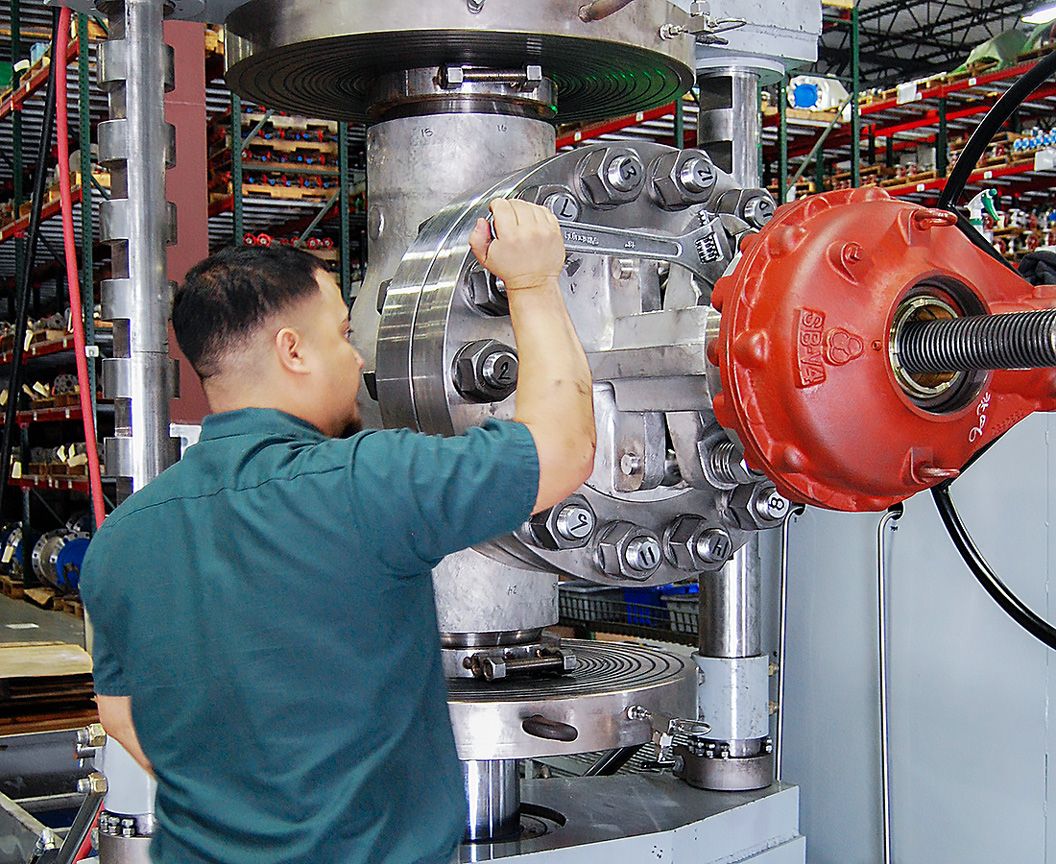

Ladish Valves manufactures various valves for diverse applications. We engineer, assemble and test our valves here in the United States. When you work with Ladish, you have greater insight into the specifications of your valves. Our products are fully traceable and meet industry certifications (API, ASME, etc.). We take pride in being able to produce and deliver our valves in short lead times, meeting the demanding requirements of our customers.

Inspection and Quality Assurance Services

Ferrite Testing

Radiographic

Examination

Gas Testing

Liquid Dye Penetrant and Mag Particle Examination

Clean Room Services

Positive Material Identification (PMI)

Cryogenic Testing

Discover corrosion-resistant solutions for Gas Processing & LNG.

Engineering and

Simulation Capabilities

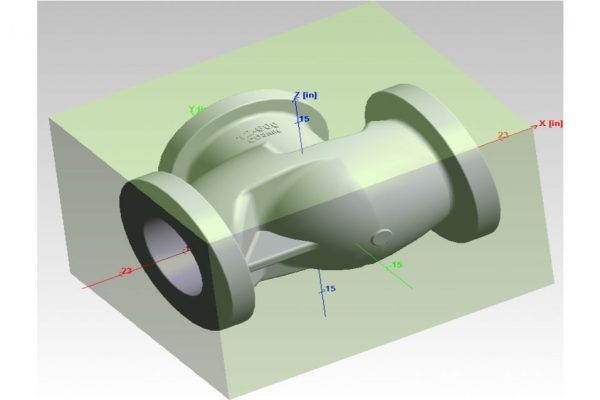

3D CAD and Solidification Modeling

This process enables our engineering team to quickly transform new ideas into great products. This method allows us to create photo-realistic renderings for product literature and catalogs, and we can produce valve products with improved durability.

We can optimize margins and compare design alternatives to meet specific customer requirements. The solidification modeling process also facilitates the design of new patterns with our foundry partners. Last, it enables us to verify and improve current patterns and design new ones.

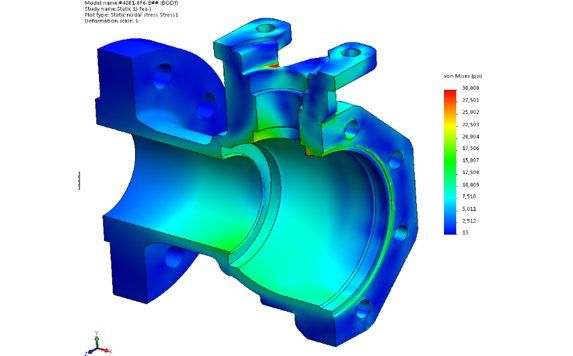

Finite Element Analysis (FEA)

FEA allows us to test cast models digitally. This can produce valuable insights early in the design process. It also enables us to unlock reductions in weight and material costs.

FEA gives us the ability to simulate products with the same service conditions they would encounter in the real world. With finite element analysis, our engineering team can maximize the quality of our products while reducing the costs required for live prototypes and testing.

Why It Matters to You

Ladish uses sophisticated tools and expert methods to not only create exceptionally well-made valves, but to provide various benefits to our customers. Our procedures enable us to reduce lead times and get our products to our customers quickly. Our valves are also fully traceable.

We perform quality assurance to ensure our partners get the perfect products for their needs, ensuring compliance with custom specifications. The Ladish approach provides streamlined engineering collaboration.

Ready To Talk?

Have a question? Our team is ready to talk. Whether you want to inquire about engineering support, quotes, specs, documentation, or lead time requests, we’d be happy to provide an answer.