Severe Service Ball Valves for Power

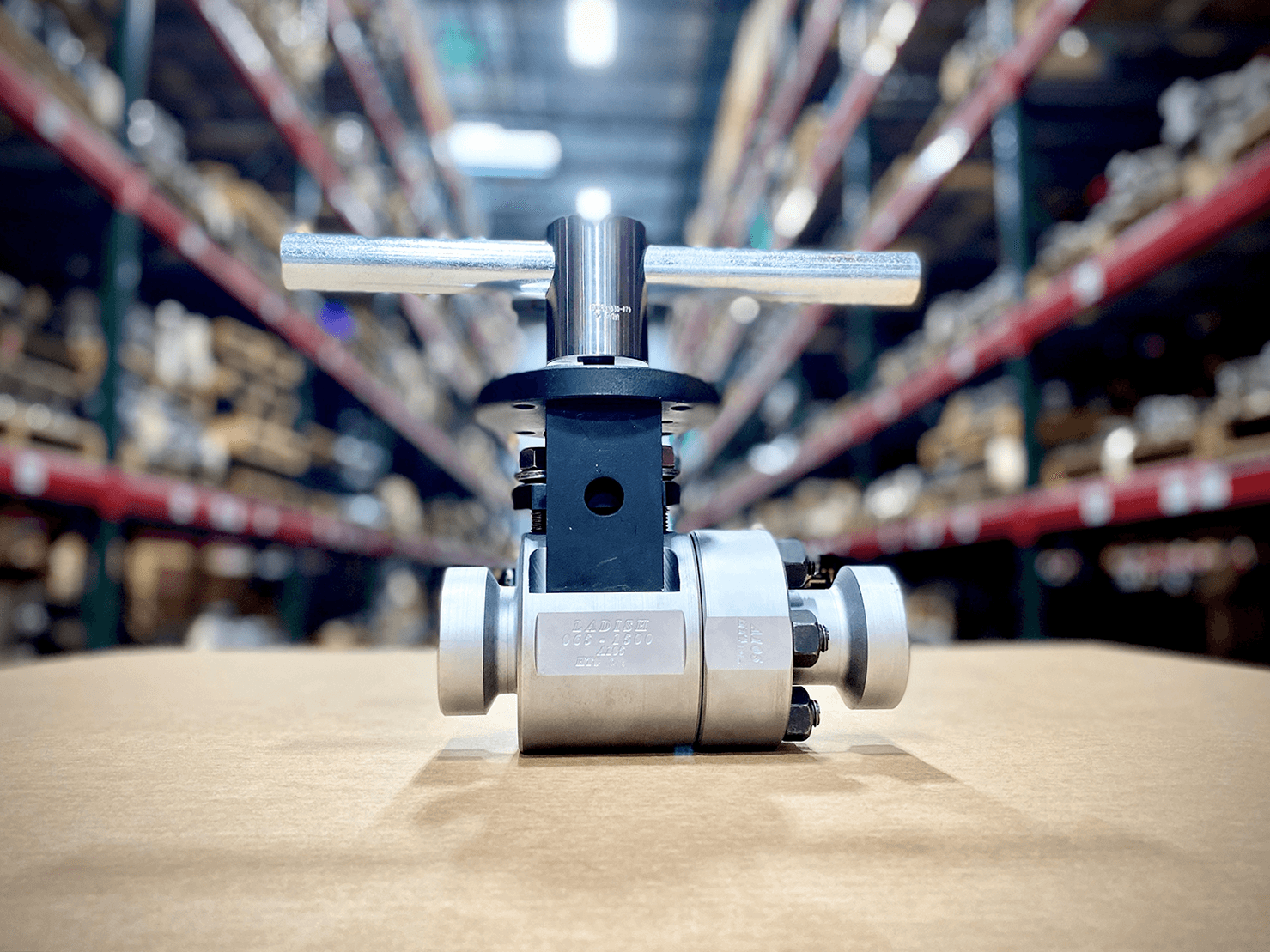

Fusion T-Series Ball Valve

A FUSION OF THE BEST OF COMPETING DESIGNS

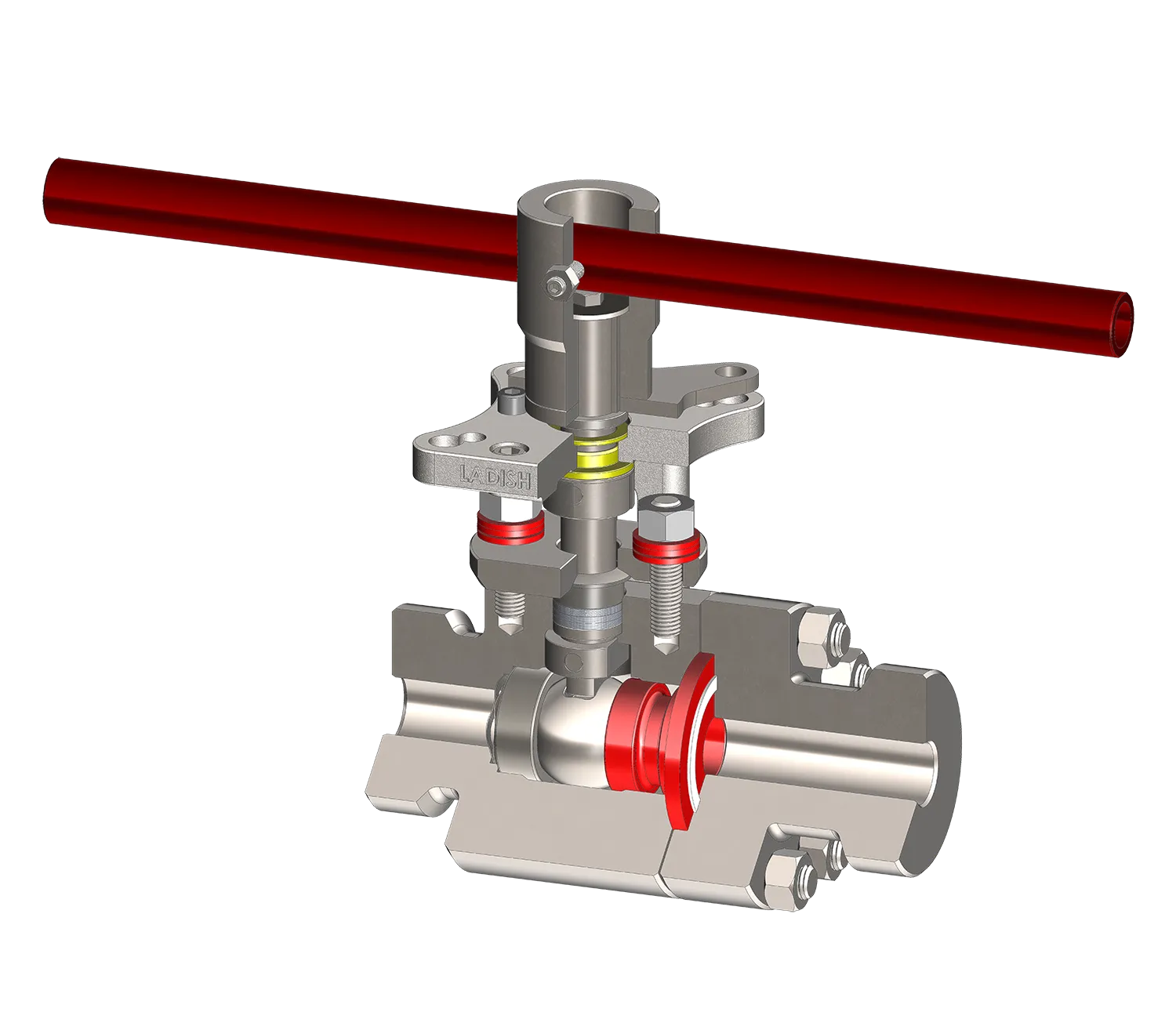

The Fusion Power Ball Valve is engineered with a single controllable leak path of the integral seat while providing thermal match of the ball and seat to achieve reliable and long-lasting shut off. Other standard options include:

Integral stem stabilization

- Oven-Fused Carbide Coatings for many times the bond strength of more traditional HVOF-type coatings while eliminating the porosity that can allow leakage.

- Precision grinding followed by 3600 Lapping to prevent “ridges” in the coating and improve sealing reliability.

- Captured Flange / Repairable Design – Tight Shutoff (TA Series)

- TA Series (Split-Body) Design for SW, BW & HUB-End Preparation available without welding or modification

- TZ Series (Uni-Body) Design for SW Preparation

- Low emission design

FEATURES & DESIGN ATTRIBUTES

Applications include high energy isolation, steam, condensate & hydrocarbons.

- Captured flange repairable design – tight shut off on split-body design

- 360 degree lapping

- Split-body design for SW & BW preparation; Uni-body design for SW preparation

- Low emissions design

- Integral actuator mounting